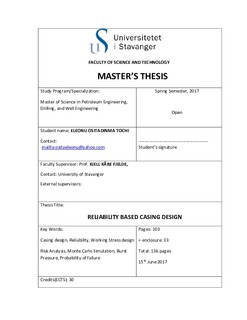

| dc.contributor.advisor | Fjelde, Kjell Kåre | |

| dc.contributor.author | Eleonu, Ositadinma Tochi | |

| dc.date.accessioned | 2017-11-01T10:17:33Z | |

| dc.date.available | 2017-11-01T10:17:33Z | |

| dc.date.issued | 2017-06 | |

| dc.identifier.uri | http://hdl.handle.net/11250/2463392 | |

| dc.description | Master's thesis in Petroleum engineering | nb_NO |

| dc.description.abstract | It is a well-known fact that wells are increasingly becoming extremely expensive and difficult to drill as well as develop due to increasing water depth, temperatures, and pressures. All these result in an increasing load that subsurface structures must bear. This has resulted in the advent of better equipment and technology to give a cost effective and safety assured project. The birth of better techniques and ideas to cheaply and safely drill wells is still ongoing. This ongoing quest can affect any area of the petroleum industry. This thesis is one of such and is aimed at improving casing design for Well integrity assurance.

This work presents the application of reliability based method in casing design/selection, relative to the traditional approach known as working stress design (WSD), which is mainly used and have its setbacks. Firstly, the conventional casing design method is discussed. The traditional working stress design depends on the load and strength of a tubular to generate a safety margin used for design. In essence, the expected loads are kept way below the strength in order to avoid failure. This failure could have a low probability of occurrence but a severe consequence if it does occur or vice versa. The issues with the traditional approach are that it promotes overdesign and is too rigid. Also, the associated risk to the design is rarely quantified giving a non-risk consistent design. In fact, in a situation where the scenario causing failure does not occur, changes cannot be made. In other words, it does not properly account for uncertainties present during a casing design. For instance, it is challenging to obtain acceptable design factor using WSD for deepwater, HPHT wells with high magnitude load. On the other hand, the reliability based approach (RBD) measures the uncertainties and risk of failure of the design. The objective of this study is to demonstrate how to perform the RBD method in casing design. The RBD method was implemented by developing probability distributions for load and strength using limit state equations such as the burst load equations, the hydrostatic pressure equations, and the Barlow’s yield strength equations. This study evaluated and compared the two casing design approaches to determine the best in terms of quantifying the uncertainties and risk in the design. A burst scenario due to kick was developed to demonstrate this method. Furthermore, a model for the load and different models for the strength were considered. Monte Carlo simulations were performed using Matlab and the codes developed can be found in the Appendix. The methodology can be used to predict the probability of failure, analyze risks and perform a sensitivity analysis. One challenge with this approach is that it takes some time to get familiar with the documentation of the methodology. Another issue is that it is difficult to know what input parameters to use for the uncertain input distributions. | nb_NO |

| dc.language.iso | eng | nb_NO |

| dc.publisher | University of Stavanger, Norway | nb_NO |

| dc.relation.ispartofseries | Masteroppgave/UIS-TN-IPT/2017; | |

| dc.rights | Navngivelse-DelPåSammeVilkår 4.0 Internasjonal | * |

| dc.rights | Navngivelse-Ikkekommersiell-DelPåSammeVilkår 4.0 Internasjonal | * |

| dc.rights.uri | http://creativecommons.org/licenses/by-nc-sa/4.0/deed.no | * |

| dc.subject | petroleumsteknologi | nb_NO |

| dc.subject | petroleum engineering | nb_NO |

| dc.subject | Monte Carlo Simulation | nb_NO |

| dc.subject | casing design | nb_NO |

| dc.subject | probability of failure | nb_NO |

| dc.subject | reliability | nb_NO |

| dc.subject | drilling | nb_NO |

| dc.subject | boring | nb_NO |

| dc.subject | well engineering | nb_NO |

| dc.subject | brønnteknologi | nb_NO |

| dc.subject | working stress design | nb_NO |

| dc.subject | burst pressure | nb_NO |

| dc.title | Reliability Based Casing Design | nb_NO |

| dc.type | Master thesis | nb_NO |

| dc.subject.nsi | VDP::Technology: 500::Rock and petroleum disciplines: 510::Petroleum engineering: 512 | nb_NO |