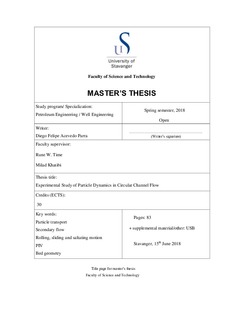

| dc.contributor.author | Acevedo Parra, Diego Felipe | |

| dc.date.accessioned | 2018-10-29T09:55:08Z | |

| dc.date.available | 2018-10-29T09:55:08Z | |

| dc.date.issued | 2018-06-15 | |

| dc.identifier.uri | http://hdl.handle.net/11250/2569904 | |

| dc.description | Master's thesis in Petroleum Engineering | nb_NO |

| dc.description.abstract | The study of liquid-particle interaction is the vital importance in many industries, especially for the petroleum well drilling and hole-cleaning operations. The data obtained from laboratory-scale experiments, simulations, and analytical models is a key factor for the success of highly costly operations in the oil & gas industry; such as drilling of oil and gas wells (cuttings transportation), gravel packing, transport of coarse material, and proppant during hydraulic fracturing.

This experimental work aims to study the liquid-particles flow in a continuous annulus channel (cylindrical cell). The setup was made of two coaxial cylinders that were fixed to the bottom plate of an “aquarium” box. The upper plate on top of the cylinders could rotate and shear the liquid inside the channel. The liquid flow, in turn, dragged the particles that were added to the test fluid beforehand. The experiments were pretended to be carried out for three different particle sizes (0.5, 1.0 and 2.0 mm), different concentrations (thin layer = one to two particle size, and thick layer = more than 3 times particle size) as well as different rotation speed (RPM) and initial bed-forms (plane and single dune).

The initial step was to perform a Particle Image Velocity (PIV) analysis to measure the liquid velocity profile in 3D: angular, radial and axial velocities. An azimuthal and close to plane Couette flow was expected, however, the results obtained from the PIV showed a rapid increase of the liquid velocity near the bottom wall, due to the action of a secondary flow inside the channel. The secondary flow went inwards at the bottom of the channel and outwards at the top.

Once the PIV technique was done, spherical aluminum particles were added into the channel and the particle flow involved during the experiments were recorded by two high-speed cameras (recording images from bottom view and frontal view). In this case, parameters such as bed morphology, particles movements and velocity, as well as bed height and the geometry of the deposit among others were analyzed. It is important to notice that due to the presence of centrifugal force the generated secondary flow drags the particles inwards to the inner wall at the channel bottom differentiating the actual experiment from the well-known flume experiments. The current annular channel can be seen as a simplified version of the annulus formed between the drill pipe and casing with the drill string rotating (upper plate rotation). | nb_NO |

| dc.language.iso | eng | nb_NO |

| dc.publisher | University of Stavanger, Norway | nb_NO |

| dc.relation.ispartofseries | Masteroppgave/UIS-TN-IEP/2018; | |

| dc.subject | petroleumsteknologi | nb_NO |

| dc.subject | petroleum engineering | nb_NO |

| dc.subject | PIV | nb_NO |

| dc.subject | particle transport | nb_NO |

| dc.subject | secondary flow | nb_NO |

| dc.subject | bed geometry | nb_NO |

| dc.subject | rolling, sliding and saltating motion | nb_NO |

| dc.title | Experimental Study of Particle Dynamics in Circular Channel Flow | nb_NO |

| dc.type | Master thesis | nb_NO |

| dc.subject.nsi | VDP::Teknologi: 500::Berg‑ og petroleumsfag: 510::Petroleumsteknologi: 512 | nb_NO |