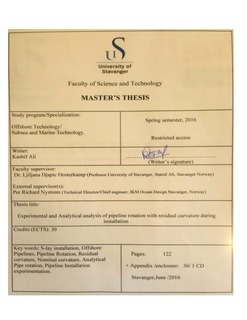

| dc.contributor.advisor | Oosterkamp, Ljiljana Djapic | |

| dc.contributor.author | ALI, KASHIF | |

| dc.date.accessioned | 2016-09-28T09:12:26Z | |

| dc.date.available | 2016-09-28T09:12:26Z | |

| dc.date.issued | 2016-06-29 | |

| dc.identifier.uri | http://hdl.handle.net/11250/2411214 | |

| dc.description | Master's thesis in Offshore Technology | nb_NO |

| dc.description.abstract | Pipelines are some of the main components of the production and transportation of hydrocarbons in offshore Oil & Gas Industry. The design, installation and operation of pipelines involve many challenging tasks. The recent decline in oil price is putting pressure on future subsea projects and leads to the stop or postponement of operators investment. While keeping the project costs as low as possible, an installation of pipelines should be done economically. As the water depth increases the loads on the pipeline changes and new challenges are experienced. A pipeline may for instance rotate during installation when there is some plastic curvature introduced or an inline structure is attached to it that causes a rotational movement. Plastic curvature can be formed due to bending of pipe beyond elastic point on the stinger (S-lay) or residual strains remain during unspooling the pipe (Reel Lay). The rotation of pipe is not desirable during the installation for inline structures i.e. Wyes or Tees at seabed which may become difficult to access and connect to. The rotation of pipelines can in other cases be desirable in case of installation of residual curvature sections to control thermal buckling and expansion effects.

The main objective of this thesis is to explain the rotation phenomena for pipelines and its dependency on different laying parameters. The next objective is to compare experimental results with the analytical energy equations.

Up until now, little information, literature and public data is available on the subject of rotation of pipelines, and most of the recent information on pipeline rotation has been performed by Geir Endal et al. (Statoil).

Three different approaches have been used to assess the pipeline rotation touch down point (TDP). The first Approach is the experimental approach. An experimental approach is applied in the thesis to study the parameters of pipeline rotation. A small model test rig was built replicating the real life pipeline installation by reel-lay and S-Lay. The experiments include all the basic pipeline installation parameters i.e. stinger/ramp, rollers, top vessel tension, bottom horizontal tension, catenary shape of the pipeline from tip of the stinger to TDP and nominal curvature of the pipeline from tip of stinger to TDP. Building the test rig took a good portion of the thesis duration. Different pre-bend sections were created with different residual curvatures lengths and strains. The pipeline installation was simulated by pulling the pipeline from the bottom side and measurement of rotation angles at TDP for various parameters were performed.

The Second Approach assessed was the analytical approach. The Analytical approach is based upon energy minimization presented by (Endal, et al., 2014). The rotation angle at TDP was calculated using the same experimental test parameters except for the pipeline bottom end boundary condition, which is free-end in the analytical approach while partially free in the experimental test.

The Third approach combined the experimental and analytical methods. The nominal curvature of pipeline was calculated by using the catenary shape of the pipeline for each top tension and water depth. The nominal curvature was then used in the analytical calculations to predict the rotation angle at TDP.

Finally, the three approaches were compared and conclusions made. Uncertainties related to the experiments were discussed and recommendations for further work outlined. Applications of the residual curvature method were also briefly discussed. | nb_NO |

| dc.language.iso | eng | nb_NO |

| dc.publisher | University of Stavanger, Norway | nb_NO |

| dc.relation.ispartofseries | Masteroppgave/UIS-TN-IKM/2016; | |

| dc.rights | Navngivelse-Ikkekommersiell 3.0 Norge | * |

| dc.rights.uri | http://creativecommons.org/licenses/by-nc/3.0/no/ | * |

| dc.subject | undervannsteknologi | nb_NO |

| dc.subject | offshore teknologi | nb_NO |

| dc.subject | S-lay installation | nb_NO |

| dc.subject | offshore pipelines | nb_NO |

| dc.subject | pipeline rotation | nb_NO |

| dc.subject | residual curvature | nb_NO |

| dc.subject | nominal curvature | nb_NO |

| dc.subject | pipeline Installation experimentation | nb_NO |

| dc.title | Experimental and Analytical analysis of pipeline rotation with residual curvature during installation | nb_NO |

| dc.type | Master thesis | nb_NO |

| dc.subject.nsi | VDP::Technology: 500::Marine technology: 580::Offshore technology: 581 | nb_NO |