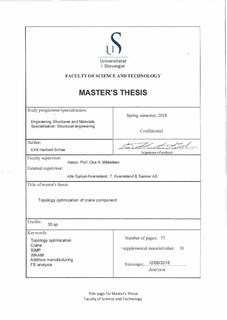

| dc.contributor.advisor | Mikkelsen, Ove | |

| dc.contributor.author | Hartveit-Schee, Eirik | |

| dc.date.accessioned | 2018-09-12T11:43:16Z | |

| dc.date.available | 2018-09-12T11:43:16Z | |

| dc.date.issued | 2018-06 | |

| dc.identifier.uri | http://hdl.handle.net/11250/2562225 | |

| dc.description | Master's thesis in Structural engineering | nb_NO |

| dc.description.abstract | Topology optimization is an important tool for conceptual design of products.

Finite element based topology optimization formulations, such as the Solid Isometric

Material with Penalization (SIMP), have proved to be a solid algorithm

for finding optimized geometries and have become widely implemented in commercial

Computer Assisted Design (CAD) software. When topology optimization

is viewed in conjunction with additive manufacturing (3D-printing), because

of it's increased shape forming capabilities, highly optimized parts can be

achieved. Technologies for 3D-printing large, metallic, load bearing structures is

still in early development, but shows great promise, like the Wire Arc Additive

Manufacturing (WAAM) method. These methods display advantages in other

areas, such as material effciency and fast deposition rate, that differentiate them

from other, established 3D-printing methods.

Topology optimization was used to develop two conceptual designs of reduced

volume compared to original component, which was an end truck of a over head

crane system developed by T. Kverneland & Sønner AS (TKS). One design

intended for traditional manufacture and one intended for additive manufacture.

Both proposed designs showed Von Mises stress above yield strength at certain

areas of the model. Sharp corners and narrow radii of hole pro les were the

main reason for this. Also, for the additive manufacture design, thin members

were observed with high stress values. Designs could be improved by round-off of sharp corners, increasing radii of hole profiles and increasing thickness of

thin members. It is believed that viable design can be achieved without drastic

changes to the designs proposed in this thesis. Proposed design for traditional

and additive manufacturing have a volume reduction of 17% and 14% respectfully

relative to volume of original component. | nb_NO |

| dc.language.iso | eng | nb_NO |

| dc.publisher | University of Stavanger, Norway | nb_NO |

| dc.relation.ispartofseries | Masteroppgave/UIS-TN-IMBM/2018; | |

| dc.rights | Navngivelse 4.0 Internasjonal | * |

| dc.rights.uri | http://creativecommons.org/licenses/by/4.0/deed.no | * |

| dc.subject | materialteknologi | nb_NO |

| dc.subject | byggkonstruksjon | nb_NO |

| dc.subject | topology optimization | nb_NO |

| dc.subject | SIMP | nb_NO |

| dc.subject | crane | nb_NO |

| dc.subject | WAAM | nb_NO |

| dc.subject | additive manufacturing | nb_NO |

| dc.subject | FE analysis | nb_NO |

| dc.title | Topology optimization of crane component | nb_NO |

| dc.type | Master thesis | nb_NO |

| dc.subject.nsi | VDP::Teknologi: 500::Bygningsfag: 530::Konstruksjonsteknologi: 533 | nb_NO |